- HOME

- Guitars in Progress

-

Finished Guitars

- 50th Guitar for Mark

- Slope Sholdered Dread

- Guitar for Rosie

- Build for David Starr

- Slope Shouldered Dred Build for Brian Baker

- Curse of the Voo'doo Guitar

- Timothy Giltzow GL-OO

- Build for Ron V

- Build for Eric Ellis

- GL-00 For Mick

- Parlor Guitar for Dave M

- GL-00 for Ron V

- Rocket Man

- Koa GL-00

- Guitar for Al

- WCG for Vaughn

- Guitar for Gracie

- RV Ziricote JMG

- News

- Footballs

- lyle

- wood

- Guitars for Sale

- Repairs

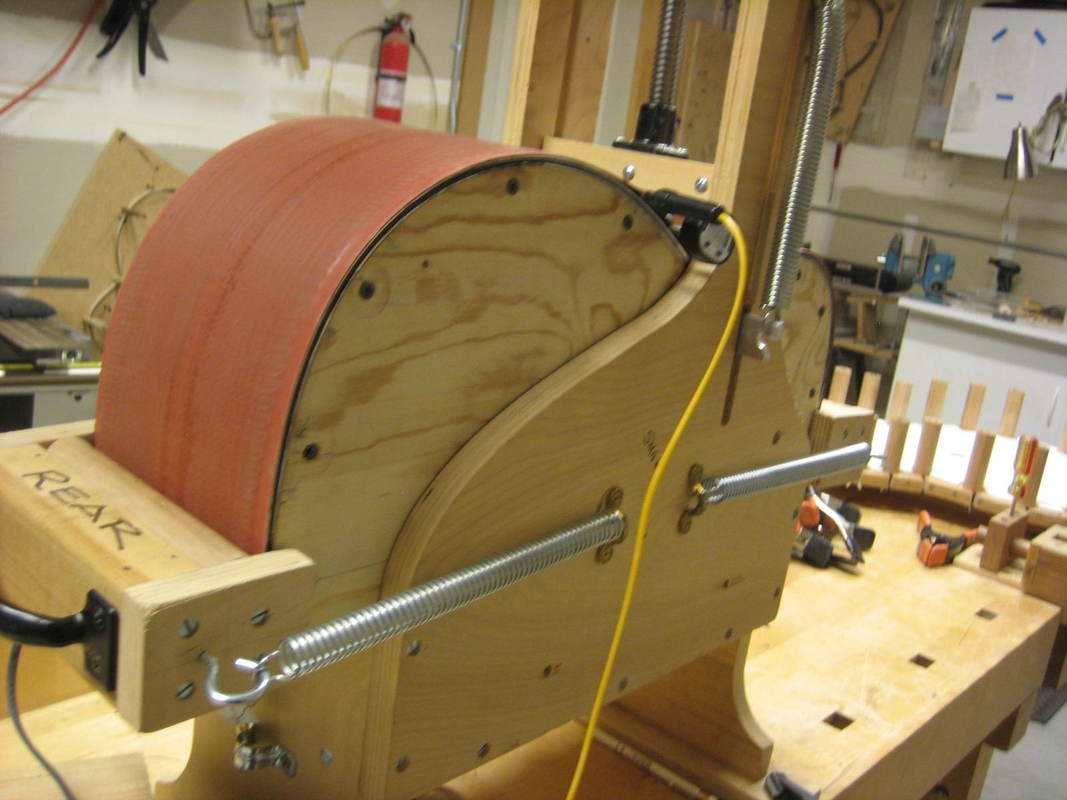

- Geared devices

Proudly powered by Weebly